Details

NIPPON EA4 FINISH

Nippon EA4 Finish is a two-pack amine-adduct cured epoxy finish for use on steel and cement surfaces where chemical, oil and abrasion resistant coating is required.Protective coatings are specialized coatings that are applied to surfaces to provide a layer of protection against various environmental factors, wear and tear, corrosion, chemical exposure, and other damaging elements. These coatings are designed to extend the lifespan of the substrate, enhance durability, and maintain the aesthetic appearance.

PRODUCT FEATURES:

• Good resistance to abrasion and mechanical damage

• Excellent on correctly prepared and primed surfaces

• Dry service temperature up to 100°C

SPECIFICATIONS

Type of Coating

Determine the specific type of protective coating required for the surface and the desired protection. This could include rust-resistant coatings, waterproof coatings, fire-resistant coatings, chemical-resistant coatings, or others depending on the intended use.

Substrate Compatibility

Check if the protective coating is compatible with the material or substrate you are applying it to. Different coatings are formulated for specific substrates such as metal, concrete, wood, or plastic. Ensure that the coating adheres well to the surface and provides optimal protection.

Protection Level

Consider the level of protection provided by the coating. This can include resistance to corrosion, chemicals, UV radiation, abrasion, impact, or other specific hazards. Look for coatings with the appropriate specifications for the intended use and the environmental conditions the surface will be exposed to.

Application Method

Check the recommended application method for the coating, such as brush, roller, or spray. Ensure that the chosen coating is compatible with the available application equipment and methods.

Coverage and Thickness

Determine the coverage area per gallon or liter of the coating and the recommended thickness for optimal protection. These specifications help estimate the quantity of coating needed for the project and ensure adequate coverage and performance.

Drying and Curing Time

Consider the drying and curing time of the coating, which indicates how long it takes for the coating to fully dry and develop its protective properties. This information is important for planning project timelines and ensuring proper performance.

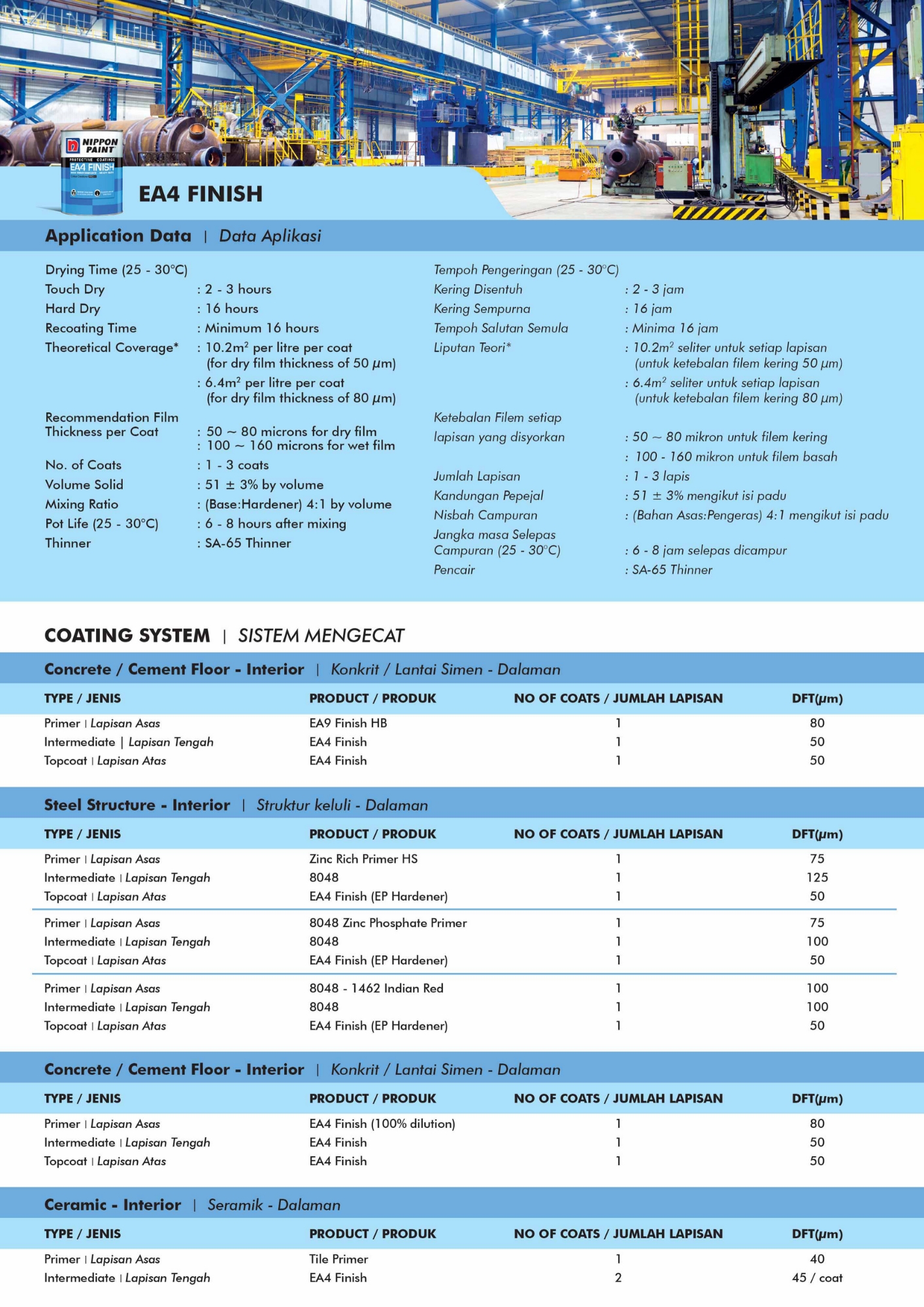

APPLICATION DATA

| Application | Brush/Roller, Airless Spray, Compressed Air Spray |

|---|---|

| Thinning | Thinner: SA-65 Thinner Brush/Roller: If necessary, add about 5% thinner by volume Compressed Air Spray: If necessary, add about 10-15% thinner by volume |

| Touch Dry / Hard Dry | 2 - 3 hours / 16 hours |

| Recoating Interval | Minimum 16 hours |

| Theoretical Coverage | 6.4 - 10.2 m² per liter per coat |

| No. of Coat(s) | 1-3 Coats |

| Packing Size | 5L |

View more about NIPPON EA4 FINISH on main site